Số người đang online: 1

Online Counter

ISCAR is expanding its range of EC-E7/H7-CF 7 flute endmills to include 3xD and 6xD length to diameter endmills. These are in addition to the already available 2xD and 4xD endmills.

Features

Advantages

When using an endmill that is longer than necessary, it is less rigid and requires reducing the cutting conditions. The new cutting length options provide an optimal tool for each machining requirement, enabling machining at the highest machining conditions.

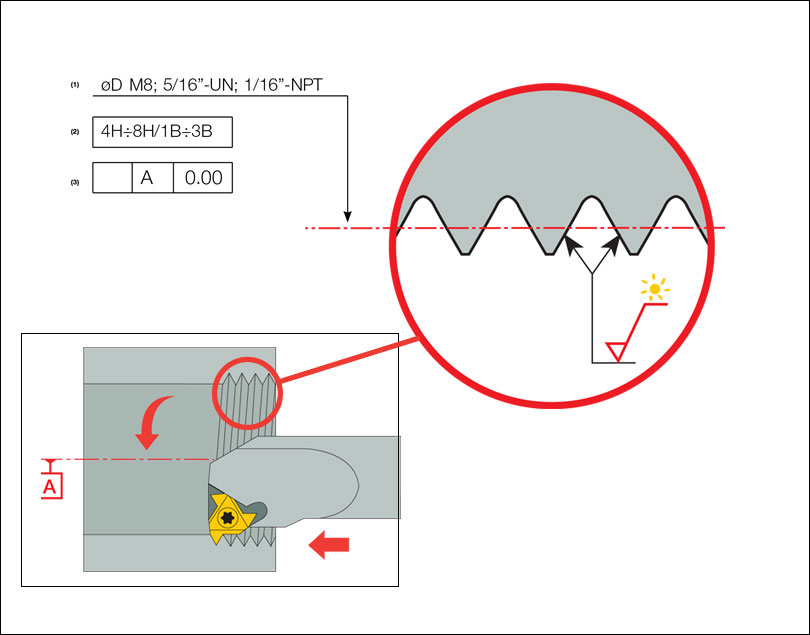

1. Trochoidal Milling

Milling a slot with a curve traced by a point on or connected with a circle as the circle rolls along a fixed straight line, preferably by using max. depth of cut.

The short contact times due to small width of cut (ae) and small contact arc reduce thermal impact of cutting edges. This allows very high feeds and speeds to be reached at a radial infeed from 0.1 to 0.3xD. This allows process reliable depth of cut from 2xD up to max. 6xD.

2. Characteristics

Benefits

Requirements

3. What to consider?

Diameter of milling cutter should be at least min. 20-30% smaller than width of slot, to ensure a small contact arc.

Width of cut should be set around 5 to max. 10% of cutting diameter.

This is calculated according to the number of flutes, workpiece material and contact arc.

Feed per tooth should also be considered, as the radial infeed during circular milling differs from standard trimming operations.

4. Formula and calculation basics for trochoidal milling

| Slot width W: | |

| Minimum slot width: | Wmin = 1.2 x Dtool |

| - This avoids an overlarge tool engagement angle and problems with chip evacuation | |

| Maximum slot width: | Wmin = 1.5 x Dtool |

| - avoid too many idle movements (productivity) | |

| Tool diameter Dtool: | |

| Minimum slot width: | Dtool (min.) = W x 0.6 |

| - avoid too many idle movements (productivity) | |

| Maximum slot width: | Dtool (max.) = W x 0.8 |

| - This avoids an overlarge tool engagement angle and problems with chip evacuation | |

| Width of cut ae: | |

| ae calculation: | 0.05... 0.1 x Dtool |